Sanding floors requires using heavy power tools and can be extremely laborious work, not to mention potentially dangerous, without taking proper precautions and safety precautions. Obtain the Best information about wood floor sanding.

The main machine utilized is a drum sander, operated from a standing position. An edger may also be required to reach corners and edges.

The Basics

The drum sander is the go-to machine for most floor sanding needs and operates best from a standing position. However, for tight areas near walls or where walls come close together, the edger comes in handy with its 7” diameter spinning disc that allows access to difficult spots that the drum cannot.

The initial step should be to assess if your floorboards are bowed or dipped, as this could prevent an even treatment by your sander, necessitating diagonal sanding across all floorboards to ensure all are treated equally.

Once you’ve finished with the rough grit sanding process, vacuum the floor before starting over with successively finer grits (e.g., 60, 80, and finally, 100 or 120 grits) until your floor is smooth and ready for staining or finishing. Make sure you vacuum between treatments as well as replace clogged sandpaper when necessary.

Another tip when sanding is to lower the sander as you move forward instead of raising it, a process known as feather cutting in. This prevents harsh lines from appearing near where you stop sanding; plus, this saves time because less time will pass with the sander touching the floorboards!

Safety First

As with any power tool, floor sanders must be handled carefully to prevent damage to both the floor and injuries to yourself or others. For optimal use and to help avoid accidents, please read these tips on proper floor sanding use.

Before beginning, check that the floorboards are flat and square, without protrusions of nails or hardware such as staples that might damage sander belts/discs (which are expensive at rental centers), as hitting one may result in unsightly marks on your floor.

The use of appropriate sandpaper is equally essential and requires using different grits sequentially in order to achieve the desired results. If this process is new to you, find an expert willing to guide you through it before renting equipment.

Personal protective equipment (PPE) is essential when it comes to sanding floors since all that dust can irritate both lungs and eyes. Make sure you invest in a good cartridge mask, safety glasses, or washable earplugs, as well as rubber gloves, in addition to buying cartridge masks for optimal protection.

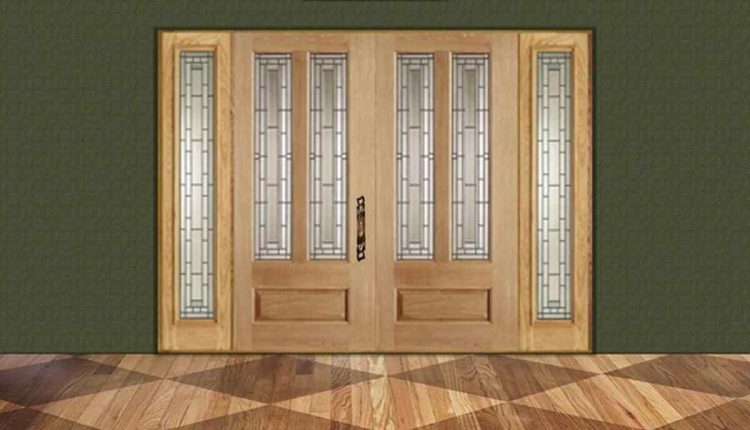

Close any doors leading to other parts of your house and open windows for adequate ventilation, tape off electrical sockets and switches so sanding debris does not contact them, and keep your workspace free from debris to complete your project quickly and easily. Also, make sure that dust collection bags are regularly emptied.

The Equipment

Flooring professionals utilize various forms of floor sanding equipment when performing refinishing work, with drum and orbital sanders being the most commonly employed methods. Edgers may also be used in tight spots like under radiators or around fireplaces. When choosing your sander, make sure it offers quality performance in terms of size/power/dust collection/wheel durability/brand reputation/cost, as all these factors will affect the results of the refinishing project.

Before beginning sanding, be sure to inspect the floor for protruding nails or staples that need to be removed or hammered down to avoid damaging the machine. Furthermore, it is crucial that all wheels of both drum and orbital sanders be checked as any debris on these machines may transfer directly onto the flooring surface when they move – this debris may even result in serious injury if mishandled! Also, keep in mind these machines are cumbersome and must be handled with care to prevent accidental injury from happening during operation or handling!

Are You Looking to Become a Flooring Sander or Learn This Trade? Those interested can obtain information regarding training and apprenticeship opportunities by contacting local union offices, building contractors, or state employment services. Once fully trained workers have finished sanding floors, they can start their sanding and finishing businesses; once complete, they sweep and vacuum before applying a sealer to seal up wood pores before staining or painting their chosen color to finish it all off!

The Process

Most wood floors will require sanding at some point in their lifetimes – either because of old age and the need for refinishing or the removal of an original coating and new flooring installed. Floor sanders are machines specifically designed for this task and come in various sizes and types – usually operated by one person for maximum convenience – to achieve this task. They feature multiple fixtures and sandpaper options that offer different degrees of smoothness to wood surfaces.

Before beginning the sanding process, you must prepare the room by clearing away any furniture and covering all surfaces with plastic sheets to protect them from dust. Be sure to cover any vents, outlets, or windows with masking tape or painters’ tape – and wear a respirator mask during this entire process for added safety.

Floor sanding typically takes place using a drum sander operated from a standing position, although an edging sander may also be utilized in specific locations where the drum cannot reach. When working along the grain of floorboards, it is essential to always sand in its direction to avoid stop marks appearing at their edges.