Precision mold parts are used to craft plastic products requiring high dimensional accuracy while being robust and tough enough to withstand repeated minor energy impacts, contact stresses, and fatigue fractures. What do you consider about Precision Mold Parts?

Selecting a plastic resin with low shrinkage is critical for precise molding and requires an in-depth knowledge of material properties, machine capabilities, and skilled operators.

Precision Machining

As its name implies, precision machining involves using an automated system to follow digital blueprints to cut parts precisely. It enables excellent features and tight tolerances, which are crucial when components must fit together seamlessly in an assembly. Precision machining can also produce intricate designs or complex shapes that would otherwise be difficult to create manually.

Prior to machining any component or part, machinists must carefully analyze engineering prints and digital models that serve as guides. This means analyzing dimensions, radii, depths, tolerances, and surface finishes specified in the design—details that ensure the end product meets all requirements and specifications.

Machinists use sophisticated measuring and inspection tools, including coordinate measuring machines (CMMs) and optical inspection systems, to verify the quality of the final product before shipment and reduce or eliminate internal part defects such as short shots, flashes, bulges, or cracks.

Precision injection molding requires constant monitoring, optimization, and fine-tuning to deliver consistent results with tight tolerances. Skilled operators and engineers are essential to ensure the process runs efficiently every time.

Multi-Layer Technology

Micro injection molding technology utilizes precise machine movements to produce very thin-walled parts with delicate structures. It’s great for creating optical components or small precision parts like connectors. Furthermore, precision injection molding can achieve high tolerances and exact specifications without needing further adjustments or inspections after the forming process.

Selecting the ideal plastic resin is critical for precision injection molding. Different plastic varieties have differing shrinkage rates and elasticity properties, which impact the size of a finished part. Some plastics retain their elasticity even at higher temperatures, while others only shrink a certain percentage.

Acrylonitrile butadiene styrene (ABS) plastic can be injected precisely and with excellent dimensional accuracy due to its lower shrinkage rate, while polypropylene has more comprehensive shrinkage ranges, which may not suit precision injection molding applications. Some molders achieve the required precision by adding filler materials such as glass and mica into their resins – this increases product structure while decreasing shrinkage levels to an acceptable level.

Strict injection molding process control is also vital for precise injection molding. This includes monitoring temperature, pressure, cycle time, and other factors that will determine the quality of plastic components produced during injection molding. Molders can adjust specific parameters by conducting trial runs and monitoring their results to address short shots, warping, and surface defects in plastic components created via this method.

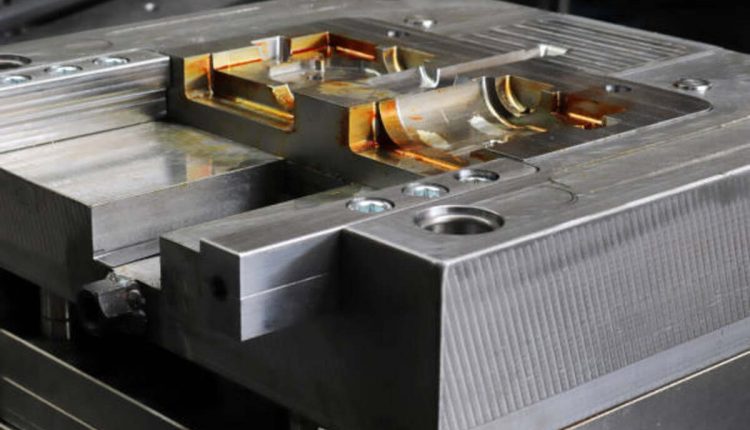

Optimal Mold Design & Fabrication

Optimizing mold design is central to precision injection molding. This involves minimizing the size and shape of injection gates to ensure material flows evenly throughout the product, as well as installing an effective cooling system that reduces cycle times while improving overall efficiency. Furthermore, having a well-crafted parting line helps prevent flash formation while simplifying mold assembly.

Precision molds must have sufficient strength and toughness. Precision molds often operate under harsh conditions, subjecting them to large impact loads, which could cause fractures brittle fractures that can occur over time. A mold’s or tooling component’s toughness depends on factors like carbon content, grain size, and microstructure – so making sure its components have enough of these qualities is also critical.

Precision molding requires materials with low shrinkage rates; unfortunately, not all plastic resins offer this feature. Many molders opt to achieve higher tolerance levels by adding filler materials such as glass granules to their plastic resin, helping narrow its shrinkage range and lessen the pressure-induced warping of their product. Furthermore, additives offer cost-effective ways of meeting this standard of precision needed in their projects.

Optimal Material Selection

Precision molding requires extreme accuracy in both mold design and material selection. Molds themselves must be constructed of highly high-grade materials and manufactured using state-of-the-art CNC machining to produce precise parts with complex geometry and tight tolerances. Furthermore, stringent heat treatment processes must ensure that plastic injection can withstand both pressures and temperatures associated with precision molding processes.

The selection of an appropriate plastic resin is of critical importance in order to achieve precision results. Selecting a plastic with lower viscosity can increase injection flowability, which is necessary for precision results. Furthermore, choosing one with a narrower shrinkage range would be more suitable; polypropylene and acrylonitrile butadiene styrene (ABS) have wide shrinkage variance that makes them unsuitable for precision molding processes.

Understanding the properties and capabilities of any given plastic resin is integral to precision manufacturing. With the Caliber team’s help, select the materials most suited for your product based on factors like print tolerances, finish requirements, and cycle time requirements. Proper selection will result in high-quality parts that are cost-efficient and scalable.