Billet technology has long been recognized for its quality, customer service, and engineering and machinist teams that take great pride in their craft. Additionally, their knowledgeable support staff offers before, during, and after-sales support services.

The UPR Catch Can Diffuser effectively prevents oil contamination by employing an extended multi-level design, which allows oil and vapor particles to condense into a liquid state before dispersing into its outlet chamber.

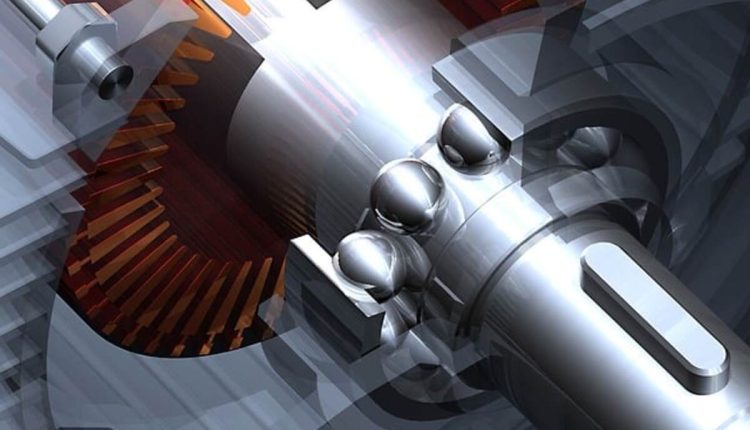

High-Quality CNC Machining

CNC machines allow manufacturers to produce intricate and precise products and components with exceptional precision. Pre-programmed computer software outlines the movement of factory machinery and tools, eliminating human error risk. CNC technology is especially beneficial for industries requiring strict adherence to strict quality standards; for instance, medical device makers would benefit significantly from this process when creating exact equipment like metering pumps and ingredient dispensing nozzles.

By employing computer programs, precision CNC machines remove material from solid pieces of metal to form it precisely to specifications, enabling manufacturers to achieve tight tolerances quickly without making multiple attempts to get it just right. Owens Industries utilizes CNC machining technology to produce high-precision parts and components for clients in the aerospace and automotive industries and medical-grade equipment like surgical instruments and orthopedic implants.

When outsourcing CNC machining projects, the right supplier must be chosen with the appropriate equipment and skills to ensure high-quality work. An experienced machinist can ensure that a CNC machine is set up and operated properly, thus reducing errors. In addition, an experienced machinist can ensure raw material quality meets industry standards; However, CNC machines can reduce many human errors from production lines, and low-quality or defective materials will still produce subpar products.

Manufacturers should look for suppliers who comply with ISO 9001, which applies to most manufacturing processes; some industries require additional certifications, such as ISO 13485 for medical devices or ISO 16949 for auto parts.

Selecting suppliers with appropriate equipment can significantly lower costs and boost productivity during manufacturing processes. CNC machining in China, in particular, is well-renowned for its competitive prices and fast production speeds; due to China’s expansive infrastructure and technological developments, its success as a global manufacturing industry makes it an attractive destination for outsourcing CNC machining services. Furthermore, China boasts multilingual staff and efficient communication channels, which enable businesses to express their needs directly to Chinese suppliers easily.

High-Quality Finishing

Surface finishes add beauty and protect products from corrosion and wear by providing presentable surfaces that look unique yet presentable at a glance. A coat of paint may help stop erosion on steel and aluminum panels, while stains can protect log homes against water damage and mildew growth.

The finish is often a garment’s first impression upon someone, even before its fabric or pattern. A good finish can elicit compliments and leave an unforgettable first impression, not to mention its lasting value as a durability measure. Garments generally fall into two categories of finishes: construction finishes (for solidity) and decorative finishes (with embellishments making clothing appealing)

The best finishing products last longer and require less maintenance while meeting environmental standards and being formaldehyde-free. Furthermore, they can be applied to various materials and withstand different climate conditions, making them ideally suited for yachts and cars and wooden or metal furniture pieces.

Selecting the ideal product for your project requires carefully evaluating your skills, needs, and preferences. For instance, when applying a wood finish with a sprayer, it’s essential to consider your experience level and the complexity of your workpieces. Safety considerations must also be considered; painting and staining projects typically necessitate gloves, long pants, closed-toe shoes, masks, and adequate ventilation in the workspace.

Custom Machining

Metal fabrication experts rely on rapid prototyping and custom machining as essential tools for managing complex production projects. These innovative tools encourage collaboration, communication, and imagination throughout the development process – enabling teams to explore various designs, evaluate their impacts, and gather consumer input before making large-scale investments for mass production. As a result, businesses become industry leaders through data-driven processes with simplified blueprints that save time and money.

Engineers often create innovative production projects that require components that don’t exist elsewhere – whether simple parts like nonstandard-sized gears or buttons or entirely new inventions that manufacturers do not possess the resources for mass-producing.

Custom machining of parts often has specific requirements that cannot be fulfilled with standard metals, such as lightweight, durable, or water-resistant material needs. Custom-made machining works by computer controlling a machine that cuts out blocks of raw material until an ideal shape has been obtained.

Custom machining companies provide invaluable services for many industries. Customers looking for customized metal parts for aircraft, automobiles, agriculture machinery, and construction equipment can contact these professionals for help. Their staff uses various production methods, including CNC milling and turning. CNC turning involves rotating metal rods through CNC-operated cutting tools, which remove parts of material by turning.

Aerospace and defense OEMs place great emphasis on flight safety. OEMs in this sector often utilize customized machined parts as part of their OEM solutions to mitigate challenges they encounter on the job, such as airborne debris or adverse weather conditions. Aviation has also extensively used CNC machining; commonly manufactured components by these firms include wing flaps or landing gears.

Consumers today increasingly favor products with unique designs and appearances, often willing to pay more for limited availability or scarce supplies produced by trusted brands offering excellent customer service. Custom machining providers can meet these expectations and deliver superior quality for prototypes and bulk orders.

Custom Finishing

The CFF team’s expertise lies in recreating fabrics, finishes, and paint chips into unique finishing applications for moldings, door trims, furniture, or any other piece that needs custom looks.

Quality engineering is central to any successful custom finishing system, and SK2 has the know-how to deliver customized solutions tailored specific experientially to your needs. Our engineering team can design a system tailored to current operational space limitations and anticipated growth plans.

Virtual reality designs from SK2 allow you to virtually walk through your new pre-built home before its walls go up, providing an invaluable understanding of materials and finishes selection.