Hi and welcome to the interesting world of cylindrical ball production! These uniquely shaped items are more than just engineering marvels; they are vital components in a variety of applications, ranging from industrial equipment to recreational equipment. Whether or not you’re curious thoughts or a manufacturing professional, focusing on how these cylindrical wonders tend to be crafted offers both interest and insight. So, a few embark on a journey to obtain the secrets behind the development of cylindrical balls.

Knowing Cylindrical Balls

To truly prefer manufacturing techniques, it’s necessary to grasp what cylindrical golf balls are and why these people matter. These objects mix the qualities of each cylinder and sphere, providing unique benefits in contact form and function.

What Makes a Golf Ball ‘Cylindrical’?

A cylindrical golf ball is essentially a sphere prolonged along one axis, creating a shape that retains the actual rolling capabilities of a world while providing the online stability of a cylinder. This original geometry makes them particularly within applications requiring controlled motion.

Applications Across Industries

Cylindrical balls are put in place in numerous industries. In the world of production, they’re key to conveyor techniques and mechanical bearings, wherever their shape aids in sustaining direction and stability. Additionally, they appear in consumer products, from toys to sports gear, where their form may enhance functionality and consumer experience.

The Physics Right Behind the Shape

The distinct style of cylindrical balls lends these people specific physical properties. Their very own design allows for a lower running resistance compared to purely circular objects, which makes them useful in mechanical systems. This kind of balance of rolling alleviates directional stability so they’re widely applied.

The Importance of Manufacturing Precision

Excellence is paramount when manufacturing cylindrical balls. Even the tiniest deviation can lead to significant functionality issues, underscoring the importance of particular manufacturing processes.

Ensuring Regularity and Balance

Uniformity in proportion and shape is crucial intended for cylindrical balls, especially in apps like bearings, where a minor inconsistency can lead to failure to function properly. Achieving this level of excellence requires advanced measurement instruments and meticulous quality command protocols.

The Impact of Excellence on Performance

In top-end environments, such as industrial machines, precision affects not only typically the efficiency but also the extended life of the cylindrical balls. Appropriately manufactured balls ensure sleek operation, reducing wear and tear on machinery and extending service life.

Difficulties in Achieving Precision

Reaching the necessary precision in manufacturing cylindrical balls poses several difficulties, including material selection, sustaining consistent production environments, as well as investing in high-quality equipment. Conquering these hurdles is crucial with regard to producing reliable, high-quality items.

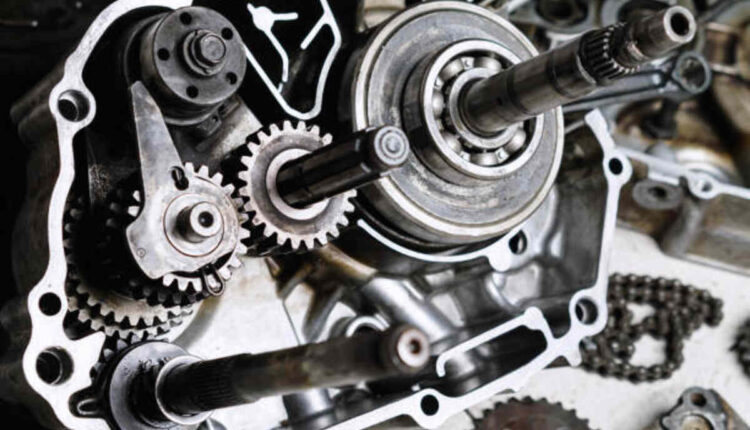

Techniques Used in Manufacturing Cylindrical Balls

The manufacturing associated with cylindrical balls involves a number of techniques, each with its personal set of advantages and difficulties. Let’s explore these techniques in detail.

1 . Casting

Throwing remains one of the most traditional and flexible methods for manufacturing cylindrical golf balls. The process involves pouring smelted material into a mold which defines the ball’s cylindrical shape.

The Versatility Associated with Casting Materials

Casting enables the use of diverse materials, from metals like aluminum as well as steel to plastics, every offering different properties as well as applications. This versatility can make casting a popular choice for large-scale production.

Steps in the Sending Your Line Process

The casting course of action includes creating a mold, being served the molten material, soothing, and finally removing the solidified ball. Each step requires excellence to ensure the final product fits the desired specifications.

Addressing Exterior Finish Challenges

One of the main issues of casting is obtaining a smooth surface end. Post-casting treatments, such as buffing or coating, are often needed to enhance the ball’s appearance and satisfaction.

2 . Forging

Forging consists of shaping material using compressive forces, a technique that has gone on for centuries but remains remarkably relevant today.

The Science Involving Forging Strength

The forging process aligns the material’s internal grain structure, increasing the strength and durability of the cylindrical balls. This makes them suitable for applications that demand excessive resilience.

Forging Process Elimination

The process begins with home heating the material until it’s gentle, followed by shaping it and applying dies that define the cylindrical form. This method provides persistence and strength.

Limitations along with Considerations

While forging is very useful for robust and consistent shapes, it’s less suited to complex designs. The cost is dissipated and equipment also helps it be a more expensive option intended for smaller production runs.

Several. Machining

Machining is a remarkably precise method where stuff is removed from a larger wedge to create the desired cylindrical appearance.

Tools and Techniques in Machining

Machining involves various instruments, such as lathes and CNC machines, to achieve high precision. This tool can produce intricate designs using tight tolerances, making machining ideal for specialized applications.

Taking care of Material Waste

One problem with machining is the potential for important material waste. Efficient using materials and recycling tactics are essential to mitigate this concern.

Balancing Time and Cost

Machining can be time-consuming, particularly for intricate shapes. However, the excellence it offers often justifies typically the investment, especially for high-value apps.

- Injection Molding

Treatment molding is primarily employed for creating plastic cylindrical projectiles, offering speed and excellence.

The Injection Molding Course of Action

This technique involves melting plastic-type material pellets and injecting these people into a mold. Once cooled off, the mold is started to reveal the finished merchandise. This process is fast along with efficient, particularly suitable for muscle size production.

Designing Intricate Specifics

Injection molding allows for typically the inclusion of intricate specifics that other methods may well struggle with, making it perfect for intricate designs and features.

Monetary Considerations

While the initial build-up for injection molding might be costly, the efficiency along with the speed of production generally leads to significant cost savings throughout large-scale operations.

Quality Command in Manufacturing

Regardless of the manufacturing technique applied, rigorous quality control is important to ensure each cylindrical soccer ball meets the required standards.

Examining for Precision and Good quality

Quality control involves examining for size, shape, exterior finish, and material components. Advanced measurement tools along with techniques are employed to validate that each ball meets rigid specifications.

Automation in Good Quality Control

Automation has modernized quality control, with products now capable of inspecting a huge selection of balls in minutes. This not only accelerates the process but also reduces man error, ensuring consistent merchandise quality.

Continuous Improvement along with Feedback

Manufacturers often carry out continuous improvement strategies, applying feedback from quality managers to refine processes as well as enhance product quality with time.

Real-World Applications of Cylindrical Golf Balls

Cylindrical balls are essential to a wide array of programs, showcasing their versatility as well as importance across different areas.

Key Industrial Uses

Within industrial settings, cylindrical golf balls are essential components in bearings and conveyor systems, wherever their shape allows for sleek and controlled movement, decreasing friction and wear.

Daily Consumer Products

Beyond commercial uses, cylindrical balls come in consumer products like spinning pens and toys, wherever their unique shape adds performance and enjoyment.

Sports and Leisure Equipment

In sports, cylindrical balls are used in video games like bowling, where their shape contributes to the accuracy and control required for the game, enhancing both performance and pleasure.

Conclusion

In summary, the world of cylindrical balls is as diverse currently fascinating. The various manufacturing methods, from casting and forging to machining and shot molding, each offer unique gains and challenges. The precision that manufactures is crucial, ensuring these tennis balls perform optimally in their expected applications. Whether in manufacturing machinery, consumer products, as well as sports equipment, cylindrical tennis balls play a vital role in maximizing performance and user practical experience. As you encounter these physical objects in your daily life, you’ll currently appreciate the craftsmanship and detail that goes into their creation. Therefore, whether you’re inspired to help delve deeper into developing or simply enjoy the knowledge, the field of cylindrical balls is full of prospects and excitement. Happy investigating!

Read also: Transform Your Photos into Anime Art